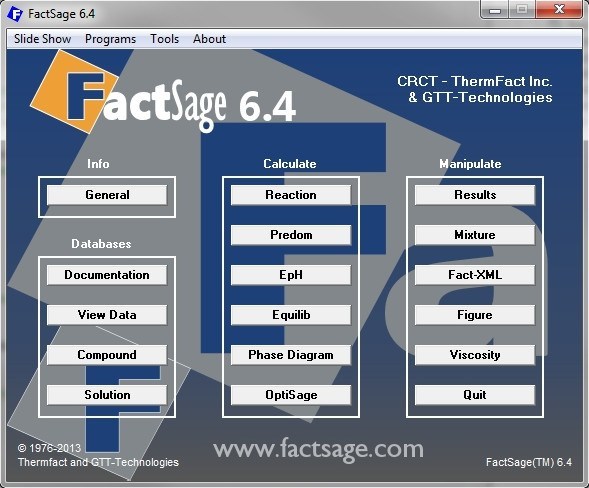

Therefore, it is commonly used in applications, such as exhaust manifolds and expansion joints. Analysis of the mold slag from the metallurgy stage indicated that altering the basicity and properties of the mold flux systematically might minimize the reaction between the slag and steel, which would achieve a coordinated control over lubrication and heat transfer.Īustenitic, Ti-stabilized 321 stainless steel exhibits a remarkable resistance to intergranular corrosion over an extended temperature range. Using this approach, we determined that ferrite nucleates grow on TiN and MgO inclusions following solidification, which then form micro-aggregates as a result of dynamic collisions and alliances. Thermodynamic calculations on the Ti xO y inclusions at different oxygen potentials were performed while using FactSage 7.2. The mineralogy and morphology of the inclusions were examined while using scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), and X-ray diffraction (XRD). Additionally, we calculated the disregistry between the metallic phases and common inclusions.

We have examined the mechanisms of floater formation during the CC of 321 stainless steel by analyzing the inclusions in the floater steel and in the 321 steel that was sampled from the mold. This causes severe surface defects or even a breakout. During the continuous casting (CC) of Ti-bearing steel, a steel lump can solidify in the mold (i.e., floater steel) more easily than in the Ti-free steels.

0 kommentar(er)

0 kommentar(er)